MENU

- Home

- Application

- Industries & Solutions

- Electronic and Electrical Industry

- DR - 150˚C Diesel Resistant Elastomeric Heat Shrinkable Tubing

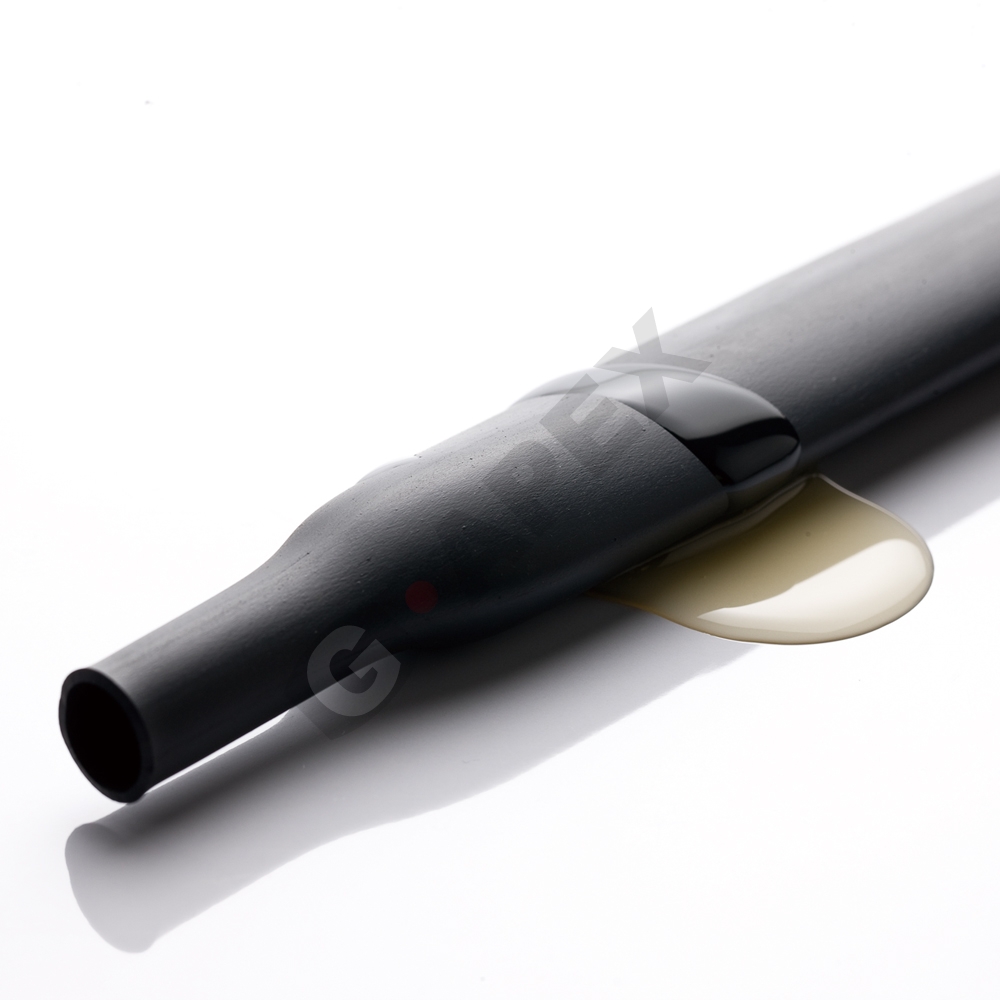

DR - 150˚C Diesel Resistant Elastomeric Heat Shrinkable Tubing

Applications

The DR product is a widely used diesel resistant rubber heat shrinkable tubing. It is made of radiation cross-linked rubber elastomers, and is suitable for providing insulation protection for wires and cables in the environment of motor oils and lubricating oils.

Operating Temperature Range

- Continuous operating temperature: -75℃ ~ 150℃

- Minimum shrink temperature: 100℃

- Full recovery temperature: Above 150˚C

Color

Standard color: black, (Special sizes and cut pieces are available on request.)

Characteristics

- Shrink ratio: 2:1

- Excellent oil and chemical resistance

- Flame retardant

- Reliable abrasion resistance

Technical Data

| Property | Specification Requirement | Test Method | Typical Value |

|---|---|---|---|

| Tensile strength | ≥10.3MPa | ASTM D2671 | ≥13MPa |

| Elongation at break | ≥250% | ASTM D2671 | ≥350% |

| Heat shock | No cracking | ASTM D2671 (200˚C/4 hrs) |

No cracking |

| Low temperature flexibility | No cracking | ASTM D2671 (-55˚C/4 hrs) |

No cracking |

| Tensile strength after aging | 70% of initial value | ASTM D2671 (150˚C/168 hrs) |

≥70% |

| Elongation at break after aging | ≥200% | ASTM D2671 (150˚C/168 hrs) |

≥300% |

| Dielectric voltage withstand | AC2500V/60S No breakdown |

ASTM D2671 | No breakdown |

| Dielectric strength | ≥11.9kV/mm | ASTM D2671 | ≥16kV/mm |

| Volume resistivity | ≥109Ω‧cm | ASTM D2671 | ≥1010Ω‧cm |

| Copper corrosion | No corrosion | ASTM D2671 (158˚C/168 hrs) |

No corrosion |

| Flammability | Self extinguishing within 1 minute after fire source removed. | UL 224 | Pass |

| Fluid resistance (23˚C/24 hrs) | |||

| Tensile strength | ≥10.3MPa | ASTM D2671 | ≥12MPa |

| Elongation at break | ≥200% | ASTM D2671 | ≥300% |

| Dielectric strength | ≥7.9kV/mm | ASTM D2671 | ≥12kV/mm |

Specification

| Part Number | Nominal Size | As supplied (mm) |

After recovered (mm) |

Standard Length (Meter) |

||

|---|---|---|---|---|---|---|

| (mm) | (Inch) | I.D. (min) |

I.D. (max) | W.T. (min) | ||

| DR0032 | 3.2 | 1/8 | 3.2 | 1.6 | 0.76±0.15 | 100 |

| DR0048 | 4.8 | 3/16 | 4.8 | 2.4 | 0.84±0.15 | 100 |

| DR0064 | 6.4 | 1/4 | 6.4 | 3.2 | 0.89±0.15 | 100 |

| DR0095 | 9.5 | 3/8 | 9.5 | 4.8 | 1.02±0.20 | 50 |

| DR0127 | 12.7 | 1/2 | 12.7 | 6.4 | 1.22±0.20 | 50 |

| DR0191 | 19.1 | 3/4 | 19.1 | 9.5 | 1.45±0.28 | 30 |

| DR0254 | 25.4 | 1 | 25.4 | 12.7 | 1.78±0.28 | 30 |

| DR0381 | 38.1 | 1 1/2 | 38.1 | 19.0 | 2.40±0.41 | 30 |

| DR0508 | 50.8 | 2 | 50.8 | 25.4 | 2.40±0.41 | 25 |

Related Products