MENU

- Home

- Products

- Heat Shrink Tubing

- Thin Wall Heat Shrink Tubing

- G5 - General Purpose, Flame Retardant Heat Shrink Tubing

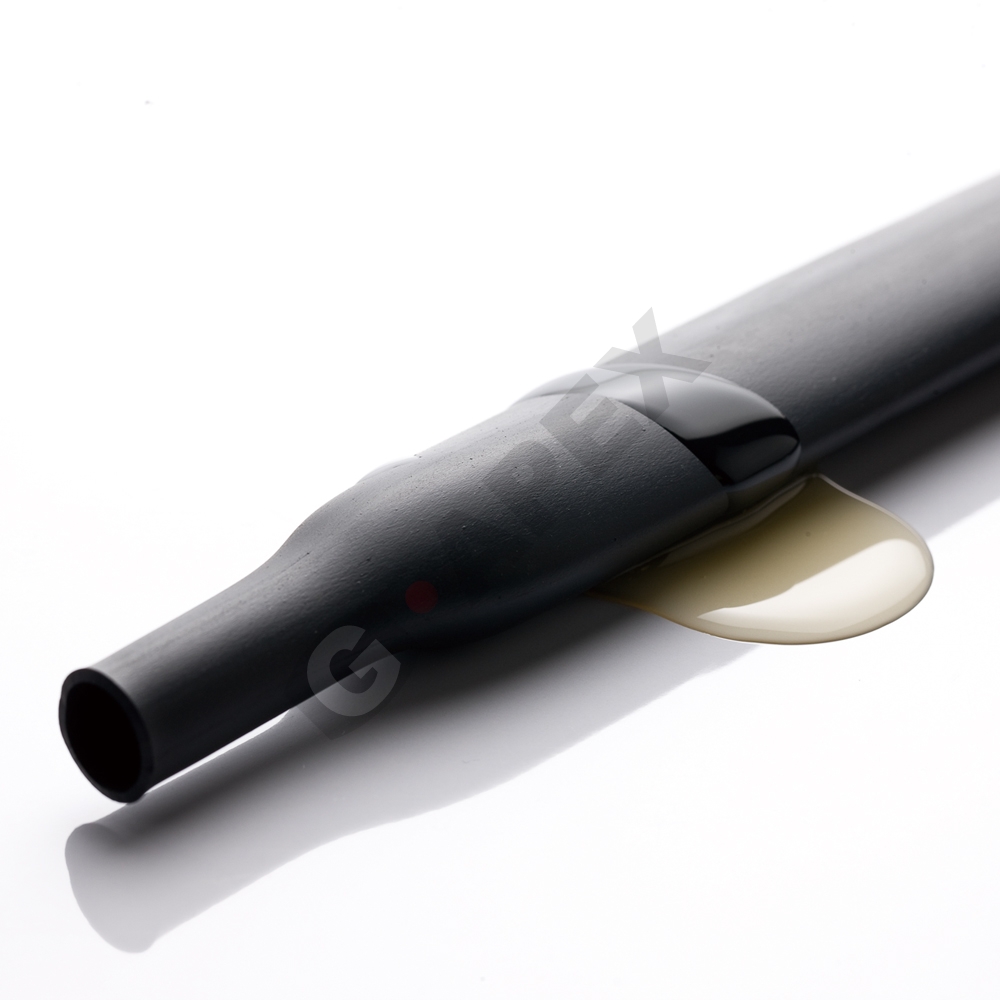

G5 - General Purpose, Flame Retardant Heat Shrink Tubing

Applications

G5 is a polyolefin material heat shrinkable tubing that complies with current environmental regulations. It is widely used in industrial and commercial fields, such as outer insulation protection of wire splices, metal pipes, electronic components, and so on.

Approvals / Specifications

![]() UL224 File no. E255532, 125℃ VW-1 600V

UL224 File no. E255532, 125℃ VW-1 600V

Operating Temperature Range

- Continuous operating temperature: -55℃ ~ 125℃

- Minimum shrink temperature: 70℃

- Full recovery temperature: Above 110˚C

Color

Standard color: black, white, red, blue, yellow, green, (Other colors, special size, and cut pieces are available on request.) 35mm ~ 180mm (35mm included) is without printing on the tubing (blank tube)

Characteristics

- Shrink ratio: 2:1

- Very flexible, high flame retardant

- Resistant to common solvent liquid

- Excellent physical, chemical and electrical performance

- Compliance with RoHS

Technical Data

| Property | Specification Requirement | Test Method | Typical Value |

|---|---|---|---|

| Longitudinal change | -10%~10% | ASTM D2671 | Pass |

| Tensile strength | ≥10.3MPa | ASTM D2671 | ≥11.3MPa |

| Elongation at break | ≥200% | ASTM D2671 | ≥400% |

| Tensile strength after aging | 70% of initial value | ASTM D2671 (158˚C/168 hrs) |

≥80% |

| Elongation at break after aging | ≥100% | ASTM D2671 (158˚C/168 hrs) |

≥200% |

| Heat shock | No cracking | ASTM D2671 (200˚C/4 hrs) |

No cracking |

| Low temperature flexibility | No cracking | ASTM D2671 (-30˚C/1 hrs) |

No cracking |

| Dielectric voltage withstand | AC2500V/60S No breakdown |

ASTM D2671 | No breakdown |

| Volume resistivity | ≥1014Ω‧cm | ASTM D2671 | ≥1014Ω‧cm |

| Dielectric strength | ≥19.7kV/mm | ASTM D2671 | 22 kV/mm |

| Flammability | VW-1 | UL224 | Pass |

Specification

| Part Number | Nominal Size (mm) |

As supplied (mm) |

After recovered (mm) |

Standard Length (Meter) |

|||

|---|---|---|---|---|---|---|---|

| I.D. (D) |

W.T. (W) |

I.D. (max) (d) |

W.T. (min) (w) |

||||

| G5-0008 | 0.8 | 1.0±0.2 | 0.15±0.05 | 0.6 | 0.25 | 200 | |

| G5-0010 | 1.0 | 1.5±0.3 | 0.20±0.05 | 0.7 | 0.33 | 200 | |

| G5-0015 | 1.5 | 2.0±0.3 | 0.20±0.05 | 0.8 | 0.34 | 200 | |

| G5-0020 | 2.0 | 2.5±0.3 | 0.20±0.05 | 1.1 | 0.34 | 200 | |

| G5-0025 | 2.5 | 3.0±0.3 | 0.25±0.05 | 1.25 | 0.42 | 200 | |

| G5-0030 | 3.0 | 3.5±0.3 | 0.25±0.05 | 1.5 | 0.42 | 200 | |

| G5-0035 | 3.5 | 4.0±0.3 | 0.25±0.05 | 1.75 | 0.42 | 200 | |

| G5-0040 | 4.0 | 4.5±0.3 | 0.25±0.05 | 2.0 | 0.42 | 200 | |

| G5-0045 | 4.5 | 5.0±0.3 | 0.25±0.05 | 2.25 | 0.42 | 100 | |

| G5-0050 | 5.0 | 5.5±0.3 | 0.28±0.05 | 2.5 | 0.52 | 100 | |

| G5-0060 | 6.0 | 6.5±0.3 | 0.28±0.05 | 3.0 | 0.52 | 100 | |

| G5-0070 | 7.0 | 7.6±0.3 | 0.30±0.07 | 3.5 | 0.56 | 100 | |

| G5-0080 | 8.0 | 8.6±0.3 | 0.30±0.07 | 4.0 | 0.56 | 100 | |

| G5-0090 | 9.0 | 9.6±0.3 | 0.30±0.07 | 4.5 | 0.56 | 100 | |

| G5-0100 | 10.0 | 10.7±0.4 | 0.30±0.07 | 5.0 | 0.56 | 100 | |

| G5-0110 | 11.0 | 11.7±0.4 | 0.30±0.07 | 5.5 | 0.56 | 100 | |

| G5-0120 | 12.0 | 12.7±0.4 | 0.30±0.07 | 6.0 | 0.56 | 100 | |

| G5-0130 | 13.0 | 13.7±0.4 | 0.35±0.08 | 6.5 | 0.69 | 100 | |

| G5-0140 | 14.0 | 14.7±0.4 | 0.35±0.08 | 7.0 | 0.69 | 100 | |

| G5-0150 | 15.0 | 15.7±0.5 | 0.35±0.08 | 7.5 | 0.69 | 100 | |

| G5-0160 | 16.0 | 16.7±0.5 | 0.35±0.08 | 8.0 | 0.69 | 100 | |

| G5-0170 | 17.0 | 17.7±0.5 | 0.35±0.08 | 8.5 | 0.69 | 100 | |

| G5-0180 | 18.0 | 19.0±0.5 | 0.40±0.10 | 9.0 | 0.77 | 100 | |

| G5-0200 | 20.0 | 21.0±0.5 | 0.40±0.10 | 10.0 | 0.77 | 100 | |

| G5-0220 | 22.0 | 23.0±0.5 | 0.40±0.10 | 11.0 | 0.77 | 100 | |

| G5-0250 | 25.0 | 26.0±1.0 | 0.45±0.10 | 12.5 | 0.87 | 50 | |

| G5-0280 | 28.0 | 29.0±1.0 | 0.45±0.10 | 14.0 | 0.87 | 50 | |

| G5-0300 | 30.0 | 31.5±1.0 | 0.45±0.10 | 15.0 | 0.87 | 50 | |

| G5-0350 | 35.0 | 36.5±1.0 | 0.50±0.10 | 17.5 | 0.97 | 50 | |

| G5-0400 | 40.0 | 42.0±1.5 | 0.50±0.10 | 20.0 | 0.97 | 50 | |

| G5-0450 | 45.0 | 47.0±1.5 | 0.50±0.10 | 22.5 | 0.97 | 25 | |

| G5-0500 | 50.0 | 53.0±2.0 | 0.55±0.10 | 25.0 | 0.97 | 25 | |

| G5-0600 | 60.0 | 63.0±3.0 | 0.60±0.15 | 30.0 | 1.17 | 25 | |

| G5-0700 | 70.0 | 71.0±3.0 | 0.60±0.15 | 35.0 | 1.17 | 25 | |

| G5-0800 | 80.0 | 81.0±3.0 | 0.65±0.15 | 40.0 | 1.20 | 25 | |

| G5-0900 | 90.0 | 91.0±3.0 | 0.75±0.15 | 45.0 | 1.30 | 25 | |

| G5-1000 | 100 | 101.0±3.0 | 0.75±0.15 | 50.0 | 1.30 | 25 | |

| G5-1200 | 120 | 121.0±4.0 | 0.80±0.20 | 60.0 | 1.40 | 15 | |

| G5-1500 | 150 | 151.0±4.0 | 0.80±0.20 | 75.0 | 1.50 | 15 | |

| G5-1800 | 180 | 181.0±4.0 | 0.80±0.20 | 90.0 | 1.60 | 15 | |

Related Products